There is a cost or costs associated with quality. We’ve heard the slogans, quality is free, or as Benjamin Franklin said “The bitterness of poor quality remains long after the sweetness of low price is forgotten”.

Why Spending Money Now Is Cheaper in the Long Run?

But there is real money involved here and if you understand that spending some money on the right things will make your business a very successful one, with big profits, no problems, and very happy customers.

The costs associated with quality are broken into three categories; prevention costs, appraisal costs, and failure costs. With the failure cost split into two; internal failure costs and external failure costs.

Looking at each in turn,

Prevention costs – are associated with preventing things going wrong.

This is the money that is spent on things like,

- ✔ Purchasing good equipment – buying the right equipment for the job

- ✔ Maintenance – ensuring everything is correctly looked after

- ✔ Writing procedures – documenting how things should be done

- ✔ Training staff – ensuring people know how to do their job correctly

Appraisal costs – are associated with checking that things are as they should be.

This is money spent on things like,

- ✔ Goods receivable – confirming that what is received is what was ordered

- ✔ Auditing – confirming that the system is operating correctly

- ✔ Monitoring and measurement – checking that what is produced is correct

- ✔ Calibration – checking that equipment is measuring correctly

Internal failure costs – are associated with fixing defects before they get to the customer.

This is money spent on things like,

- ✔ Rework or repair – correcting things that are wrong

- ✔ Scrap – product or materials that cannot be repaired or reused

- ✔ Waste – unnecessary work or stock holding due to inefficiencies

- ✔ Corrective action – activity required to find the cause of internal failure

External failure costs - are associated with fixing defects identified by the customer.

This is money spent on things like,

- ✔ Warranty claims – repair and replacement of defective items

- ✔ Complaints – work and costs associated with handling and servicing customer complaints

- ✔ Returns – handling, investigation and transport costs of rejected or recalled items

- ✔ Lost business – this is the amount of sales lost due to poor reputation

All of these costs except one can be quite accurately measured, and the one that can’t is arguably the biggest – and that is the external failure cost of lost business. If you buy something and it doesn’t do what it’s meant to, or you get bad service, or it breaks on first use – how many people do you tell? Estimates are between 7 and 10 people,so that now is potentially 7 – 10 people that won’t buy your product/service, and that’s assuming those 7 – 10 don’t tell anybody else. It is often said that one external failure costs 10 times the same failure found internally, before it got to the customer.

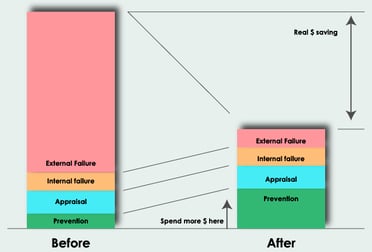

The following chart shows quite simply how if you put more money into prevention, how it can improve the overall bottom line.

With organizations that have done this what they have tended to find is that by spending more in the area of prevention and roughly the same in appraisal costs, the costs of failure fall dramatically especially the cost of external failure - those really nasty errors that get picked up by the customer.

What are some of the classic failures that produce these almost immeasurable external failure costs,

- ✘ Having a bad experience at a restaurant.

- ✘ Car breaking down straight after it’s been serviced.

- ✘ Finding the new garment you’ve just brought home has a broken zip.

- ✘ Tradespeople not turning up, or turning up late.

- ✘ Projects not delivered on time.

- ✘ Computer bugs.

- ✘ Waiting in queues.

So if you’re in the position that you can do something about this, get your wallet out – and spend some money where you need to, so that you will save in the future.